Machined Parts Las Vegas, NV

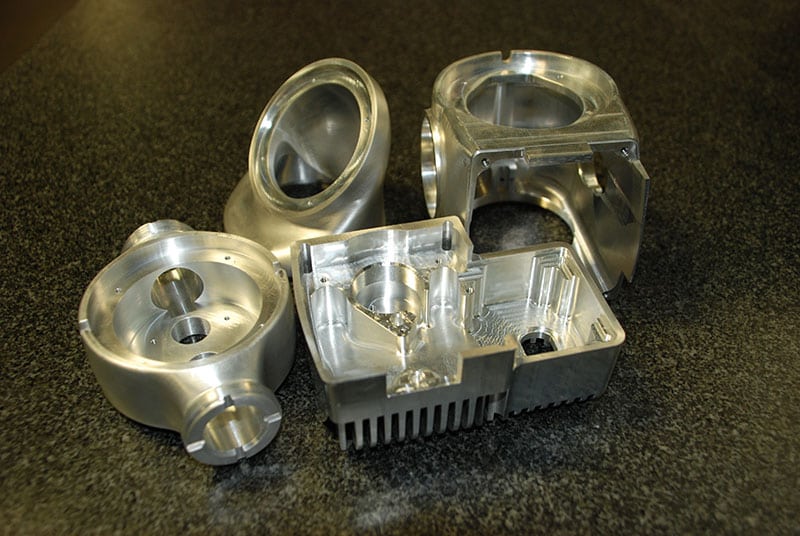

Machined Parts Las Vegas, NV. Machined parts are everywhere around you in Las Vegas, NV. From tiny metal fasteners used on the motherboard of your computer to aircraft engine components, Turning machining China Inc. has manufactured all sorts of parts using our proven process of CNC machining.

Machined parts are more than simply things built using our machinery. They are parts fabricated using our cutting machines, such as our CNC mills and lathes. Machined parts can be metal, plastic, or even some other materials on occasion, but they must come from a material that can be cut without majorly deforming. Machined parts come from a tried-and-tested manufacturing method that we have utilized as an industry standard for decades. No matter your Las Vegas, NV company’s industry, or in which component your machined parts are being employed, they meet all industry-specific certifications and standards. We guarantee it.

Turning machining China Inc. is a custom manufacturer of precision CNC machined parts. We make it simple to receive the custom machined parts you need in Las Vegas, NV. Call us today at +86-755-29621901 or reach out to us online.

What Materials Can Be Used For Machined Parts For My Las Vegas, NV Company?

Machined parts can be made from many different materials, including metals and plastics. Yet, some materials are easier to machine than others. Exceptionally hard materials are especially difficult to penetrate with a cutting tool and may cause the tool to shake or vibrate more, thus likely diminishing quality. Extremely soft materials, and materials with a low melting point, may warp once coming into contact with the cutting tool. Several of our most common machined part materials are listed below. As always, we are available to a conversation involving machining parts with other materials. Just give us a call at +86-755-29621901 or connect with us online.

- Metals: Aluminum (6061, 7075, 7050 or “aa7050 alloy”), Stainless Steel (303, 304), Magnesium, Titanium, Zinc, Brass, Bronze, Copper

- Plastics: ABS, PC, <a href="PC-ABS, PP, PS, POM, PMMA, PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK

What Are the Best Ways For My Las Vegas, NV Company to Use Machined Parts?

Machined parts are used in essentially all types of companies, throughout every industry – from medical devices to consumer goods. Some common machined parts used in a multitude of industries include:

- Fasteners

- Valve bodies

- Ball joints

- Gears

- Shafts

- Housings

- Brackets

- Rollers

If your Las Vegas, NV business is planning a production run of machined parts, call Turning machining China Inc. at +86-755-29621901 or fill out our online request-a-quote tool.

Along with our machined parts for your business in Las Vegas, NV, Turning machining China Inc. provides the following for our Las Vegas, NV clients:

- Aluminum Fabrication

- Machine Shop

- Aluminum Parts Manufacturer

- CNC Services

- Component Manufacturing

- 3D Printing Services

- OEM Automotive

- Medical Device Manufacturing

- Contract Manufacturing Companies

What Are the Benefits of Using Machined Parts at My Las Vegas, NV Company?

Machined parts from Turning machining China Inc. provide particular benefits that might not be possible with 3D printed parts or even injection molded parts in Las Vegas, NV. Some of the key advantages for your Las Vegas, NV company are:

Quality

Machined parts can be cut to a very high caliber, based entirely on your Las Vegas, NV company’s specifications and tolerances. This means our CNC machinists can take extra time on tight-tolerance workpieces and individual aspects to ensure the best quality.

Lead Times

Machined parts can be produced quicker than components made via other manufacturing processes like Las Vegas, NV molding. This is mainly due to the lack of labor-intensive tooling, being able to bank more on the CAD and CAM software our machinists use with the CNC machines. But the manufacturing process itself is also highly efficient – some of our CNC machines have rapid rates of nearly 45 yards per minute, although we don’t produce machined parts at those speeds. The one-step nature of machining and the speed of our CNC machines combine to make machined parts some of the fastest to produce, reducing lead times for shorter time-to-market and practical rapid prototyping.

Design Freedom

Machined parts can have a wide range of shapes and sizes. This is due to the fact that CNC machines are not subject to the same limitations of molding, like tapering and thin walls. Machined parts can be thick and robust, yet their features can be fine and complex. Although machined parts have some restrictions when it comes to, for example, deep channels and internal sections, machining still represents the most geometrically flexible production procedure for your Las Vegas, NV production run.

Alterations

Because CNC machined parts are made from digital CAD files, it is possible to make alterations throughout the machining procedure, up until the last minute. This is extremely favorable throughout our research and experimental development and prototyping stages, when your staff or our engineers may need to make fractional changes or clarifications to the machined part or create multiple versions. It also reduces the possibility of waste, as erroneous parts are far less likely to come about.

Strength

Machined parts are cut from solid pieces of material known as blanks, which have normally been cast or extruded. This makes them foundationally strong in comparison to, for example, 3D printed parts, which can be predominantly flimsier along one axis, where one layer is added atop the next.

Surface Finish

Machined parts completely circumvent the surface quality issues associated with molding like flow lines, jetting, and flash at the parting line. With a moderate amount of post-processing, which is achieved in our value-added services, machined parts can be brought to an extremely high standard regarding surface finish. Machining also gives a better surface finish to 3D printing, even before any secondary service has been carried out by our machinists. 3D printing can leave noticeable layer lines on the surface of the part, which must be smoothed over through chemical treatment or sanding. Machined parts do not produce these layer lines.

No Minimum Order Quantity (MOQ)

Machined parts are cost-effective and available in small quantities or even one-off parts due to the fact that they are cut directly from a blank workpiece. It is a requirement when molding parts that you fabricate metal tooling – a procedure that takes a long time and can be costly. However, machining with Turning machining China Inc. is unique in offering high-quality parts with no MOQ, making it convenient for smaller companies in Las Vegas, NV, small production runs, and prototyping.

Call us today to learn more about machined parts and our CNC capabilities for your Las Vegas, NV project at +86-755-29621901 or connect with us online.

What CNC Machinery is Necessary to Make Machined Parts For My Company in Las Vegas, NV?

The Turning machining China Inc. facility is fully stocked with high-end CNC machinery capable of manufacturing precisely machined parts in a fraction of the time compared to our competitors. Our full range of equipment includes:

- CNC Horizontal Mills

- CNC Vertical Mills

- CNC Horizontal Lathes

All mills use rotary cutting in the subtractive manufacturing process of removing materials from a workpiece, but our CNC mills combine the cutting procedure with the latest computer control to allow for rapid and accurate manufacturing. Our horizontal CNC mills quickly and accurately shape your component material to tight tolerances. Our CNC horizontal milling services benefit from the availability of our modern 3 axis, 4 axis, and 5 axis machines.

Vertical CNC mills feature spindles that are perpendicular to the ground, making them optimal for projects calling for large production runs of moderately complex parts. While horizontal mills are more beneficial in complicated milling jobs, vertical mills are adept in a wide variety of designs for your business’s project in Las Vegas, NV.

As opposed to mills, which rely on spinning of the cutting tool, lathes instead spin the workpiece as material is subtracted. In comparison to manual lathes, which require a degree of expertise to operate, CNC lathes drastically diminish the amount of labor and the probability of human error. These advantages translate into decreases in cost and defect rates for your Las Vegas, NV company.

Reach Out to the Leader in Custom Machined Parts For Your Company in Las Vegas, NV | Turning machining China Inc.

From production to prototypes, and every process in between, Turning machining China Inc. optimizes your entire Las Vegas, NV production workflow with our CNC machines and services. We are truly your one-stop shop, your single-source manufacturer, for everything regarding CNC machined parts. Our dedicated leadership team, along with our skilled and experienced machinists are passionate about supporting you, your work plan, and doing whatever it takes for you to succeed in Las Vegas, NV.

Call us today to learn more about our machined parts production and services at +86-755-29621901 or contact us online.