Multi Axis Machining

Multi axis machining. By cutting along a number of different axes, it’s now possible to create complex components that meet exact specifications with total accuracy — each and every time. The multi axis CNC machining services at Turning machining China Inc. can be used in a variety of applications, industries, and businesses across the country.

Whether you need an initial prototype or a full run of components that are identical from one to the next, we have the capability to consistently meet your production targets on time and on budget. Tell us more about your multi axis machining needs today. Give us a call at +86-755-29621901 or contact us online.

For over 22 years, our multi axis machining specialists have been providing our customers across the country with top-notch service and reliable parts and products – quicker and more affordably than our competitors. All of our partners, no matter in which industry they excel, can take advantage of the strength of more axes. Put simply, more axes means more power – leading to faster production times and quicker turnarounds, along with outstanding quality.

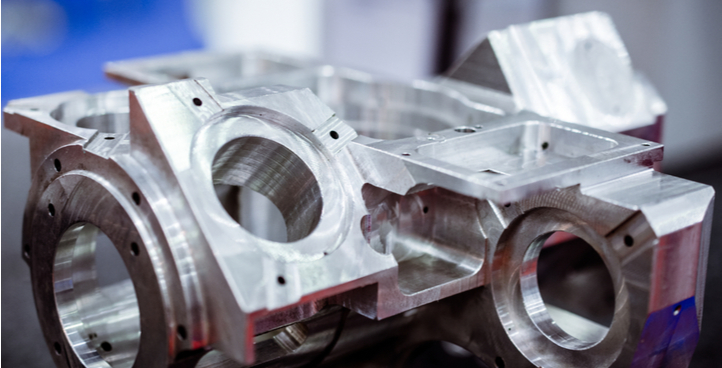

What is Multi Axis Machining?

Precision and efficiency are paramount at Turning machining China Inc.. Multi axis machining is a cutting-edge technique that involves using CNC machinery to perform operations on multiple axes at once. Our traditional 3 axis machining moves vertical on the Y-axis, sideways on the X-axis, and back-and-forth on the Z-axis. With 5 axis machining, you get two additional axes – the table rotation (C-axis) and the tilting table (A-axis). The spindle head is in closer proximity to the workpiece, allowing shorter and tighter cutting tool operation with less deflection and vibration.

5 axis CNC machines can also be used in what is known as “3+2” mode. This means that the two table axes are locked, putting the workpiece or cutting tool into a fixed position. 3+2 mode allows parts that would usually be machined on a 3 axis CNC machine to be produced on a machine that does not require as much downtime, special fixtures, loading and unloading, or changing of setups. It also allows parts that have holes or unique features on multiple faces to be machined quicker and more reliably.

What Are the Benefits of Multi Axis Machining?

Multi axis machining at Turning machining China Inc. is an efficient and economical solution with many different benefits for your company, including:

- Enhanced precision: Multi axis machining enables the production of complex parts with complicated features, like curved surfaces and undercuts, that would prove challenging using more conventional manufacturing methods. Our ability to move cutting tools along multiple axes allows us to provide our customers with greater accuracy and dimensional consistency.

- Reduced tooling costs: With multi axis machining, complex parts can often be manufactured using a single setup, minimizing the number of tool changes required, increasing uptime, decreasing human error and, in turn, your costs.

- Improved tool life: Multi axis machining allows us to prolong the life of our tools and speeds up our cycle times as a result of tilting the tool/table to maintain optimum cutting position and constant chip load.

- Expanded design possibilities: The versatility of multi axis machining opens up new possibilities. We can create highly complex components with smoother transitions and complex contours and shapes. This allows for increased innovation and the manufacturing of customized parts.

- Achieving excellent surface finishes: Using the rotating fourth and fifth axes, your part can be orientated to bring it closer to the cutting tool. When the part gets closer to the cutting tool, the tool can be shorter, allowing for less susceptibility to vibration at higher speeds, which directly impacts surface finish.

We are always investing in multi axis machines and manufacturing solutions. Being able to manufacture parts using multiple angles, arcs, and throughputs that are impossible to achieve on more traditional CNC machines easily creates parts that combine both more complex designs and tighter tolerances. Our customers trust us as they can be confident that they will receive quality parts, made to their exact standards, and built to last.

Find out about all of our unrivaled CNC machining services. Contact us online or call us at +86-755-29621901 today to get your free quote.

5 Axis CNC Machining For Your Company’s Needs

By consolidating machining and other linear axes operations into one setup, you can increase production throughput and accuracy while reducing overall waste, costly work fixtures, and cycle time. With so many different directions of work achievable with 5 axis machines, some may believe that they should only be used for specialty projects. This is not true as they can still be used for everything from highly complicated parts to relatively simple parts. Multi axis machines may even be a preferred choice when manufacturing less complicated parts. Their high speed and ease of use makes it possible for larger production runs to be undertaken while offering significant cost savings.

3 and 4 Axis CNC Milling Services

We tackle the most demanding jobs using our 3 axis and 4 axis CNC high-precision machines that cut hard-to-reach features into complex part geometry. We are committed to the continual investment in state-of-the-art equipment, innovative technology, ongoing industry training, and experienced specialists. We are ISO 9001– and AS9100-certified, and proud of it, so everything we do is rigorously quality-checked at every stage, enabling us to not only deliver exceptional components every time, but to also continually improve our processes and discover new opportunities to cut costs. It is our mission to keep prices competitive without ever compromising on the quality of the end product.

Some Applications of Multi Axis Machining For Your Company

Turning machining China Inc. is the shop to turn to for your company’s manufacturing needs. The following are examples of multi axis use in top industries:

- Aerospace Industry

- Automotive Industry

- Medical Industry

- Defense Industry

Multi axis machining plays a vital role in aerospace manufacturing, where components require complex shapes, lightweight structures, and precise tolerances. We typically use it for production of turbine blades, aircraft structures, engine components, and intricate aerospace assemblies.

In the automotive industry, multi axis machining enables the production of a wide range of precise parts. Anything from small, complex engine components and transmission parts to larger suspension systems and molds for body panels is machined in our shop. Contributing to the ever-changing technology involved and the reliability needed in the industry, our multi axis machining adapts and ensures high accuracy and repeatability. Call us now at +86-755-29621901 or reach out for an online quote for your next multi axis machining project.

Widely used in the manufacturing of medical devices and implants, multi axis machining ensures optimal fit, functionality, and patient comfort.

The defense and military industry requires highly reliable components for applications like weapon systems, military vehicles, and communication equipment. We frequently contract with companies that have governmental bids on parts and products, and they count on us to deliver to their specifications.

Leading Multi Axis Machining Services | Turning machining China Inc.

The experienced professionals at Turning machining China Inc. are ready to take on your multi axis machining project. Our centrally located machine shop is ideally situated near major interstates, railway lines, and cargo airports, allowing our clients to get high-quality parts when they need them, even on tight deadlines.

To tell us more about your project or to request a quote for multi axis CNC machining services, contact us online or call +86-755-29621901.