Comparing Additive to Subtractive Manufacturing Part 2

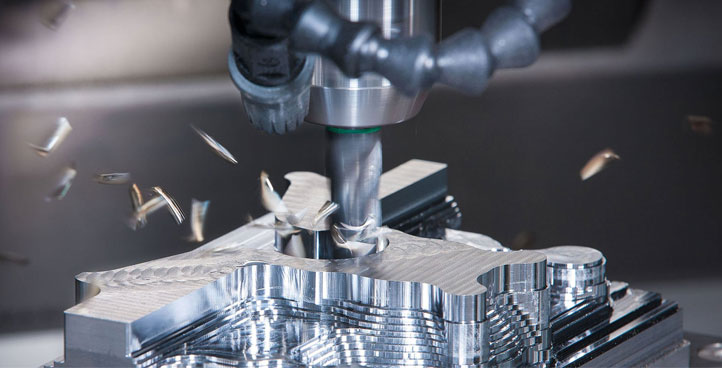

Comparing Additive to Subtractive Manufacturing

Comparing Additive to Subtractive Manufacturing Your business often has the choice between additive manufacturing, also known as 3D printing, and subtractive manufacturing, otherwise known as Computer Numerical Control (CNC) machining. Each method has its own advantages, but Turning machining China Inc. specializes in CNC machining and subtractive manufacturing.

Get a quote for your next manufacturing or prototyping project now. Contact us for a free quote or give us a call at +86-755-29621901. We have 20 years of CNC machining and subtractive manufacturing experience.

What is Additive Manufacturing?

Additive manufacturing, also referred to as 3D printing, is — in true, direct opposition to subtractive — the process of manufacturing a part/piece by the addition of material. Additive manufacturing is a process in which 3D objects are constructed from model data by fusing materials (like liquid resins) together in layers. Common to additive manufacturing is the use of a Computer Aided Design (CAD), machine equipment, and layering material. Once the CAD plan or blueprint is produced, the equipment reads data from the CAD file and adds successive layers or dimensions of object material to fabricate a 3D object.

Common Types of Additive Manufacturing:

- Plastic Additive

- Metal Additive

Plastics can be printed using a wide range of technologies, most notably: selective laser sintering (SLS), stereolithography (SLA), and carbon digital light synthesis (DLS). Plastics offer overall versatility and the ability to manufacture complex multi-material parts.

There are two main categories of metal manufacturing: power-based systems and fused deposition modeling. Both take multiple steps to complete and are not quite as versatile as plastic printings.

Disadvantages of Additive Manufacturing:

- High production costs

- Slow process

- Need for additional materials; possibly a need to transfer sites

As additive manufacturing technologies have advanced, 3D printed parts have moved outside of the research and development arenas and onto the production line. Many industries, especially those relying on smaller production runs, utilize additive manufacturing, including consumer products, energy, transportation, medical, and aerospace. But industrial adaptation has been slow and additive manufacturing is still considered by many a niche process, due to it not being an efficient way of producing parts at high volume.

Subtractive Manufacturing Solutions for Your Needs

In comparison to additive manufacturing, which is a relatively new process that might be fairly useful for prototyping but likely not yet viable for a mass-production setting, subtractive manufacturing dates back to the Ancient Egyptian civilization. Additive manufacturing does not have the capacity to support long production runs at the same facility or at practical production costs, due to the hefty per-part or -material cost. These costs will overshadow any upfront machining savings.

Turning machining China Inc. can show you the benefit of using CNC machining and subtractive machining. Whether you need a small component or a larger part for your project, or you just want to kick around ideas, give our experienced team a call at +86-755-29621901. Contact us here or feel free to request a quote.