CNC Turning in Toledo, OH | Lathe Machine & CNC Turning Center

CNC turning services in Toledo, OH. As a leading contract manufacturer of precision-machined products across the country, the turning services at Turning machining China Inc. deliver not just faster parts, but more accurate and impeccable results every time.

With thousands of square feet to house lathes, CNC turning centers, and the most state-of-the-art CNC machining technologies, we are able to produce thousands of identical pieces with exact specifications in as little amount of time as possible. Our quality management system allows us to complete each project—from concepting all the way to shipping—in the most efficient way possible.

Let us handle your short, medium, and long-run productions as well as all of your other manufacturing needs! To tell us about your CNC turning in Toledo, OH, project in more detail or to learn more about partnering with Turning machining China Inc., do not hesitate to contact us or call +86-755-29621901.

CNC Turning Services Toledo, OH

Turning is an intricate, rapid method to create custom machinery for any industry or application, and our team is proud to offer a variety of horizontal CNC turning services.

Our primary turning services in Toledo, OH, include:

- Hard turning

- Long turning up to 48 inches in length

- Large, medium, and short runs

- Prototyping

- Tight tolerances

- Short lead times

- Capability to machine most metals, alloys, certain types of plastics, as well as many other materials

By utilizing CAD/CAM software and automated CNC machining, our turning services are capable of taking a solid chunk of raw material and drilling, milling, tapping, boring, threading, or engraving it to create a finished, ready-to-ship product — all without common operator errors.

We want to be your contract manufacturer of choice when it comes to CNC lathe machine services in Toledo. Contact our team today to get started.

CNC Lathe Machined Parts in Toledo, OH – Benefits & Applications

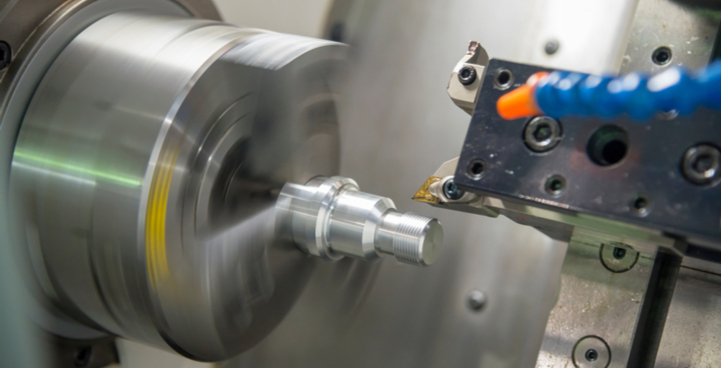

CNC turning is a process that “turns” the workpiece while metal is shaved away in a quick series of motions, allowing us to produce a large number of well-finished, identical components in a short period of time. A bar of metal is held in place by a “lathe,” which is one of the oldest manufacturing technologies in the world. It is then rotated at a high RPM while the single point cutting tool creates the designed end shape.

CNC turning works best in these applications:

- Your part has diameters or is round, tubular, or cylindrical in shape

- You have a lot of parts that need to be produced

- You have strict time limits

- You want free range of motion to make everything from straightforward to complex designs

- You need each piece to conform to the same exacting specifications

All industries including automotive, commercial, and oil and energy can benefit from CNC turned machine parts; however, the aeronautical and medical sectors—in which attention to detail is highly important— may benefit the most. The pieces created for these industries can range from simple gears to complex curved components and more. Examples include bellows, bars, tubes, shafts, knobs, pulleys, bushings, flanges, etc.

A CNC turning machine can certainly be used in a variety of ways to meet your needs — contact us to see what CNC turning in Toledo, OH, can do for you!

Turning Center vs. Lathe Machine

At Turning machining China Inc., we have both lathes and turning centers in our facility, which gives us the unique advantage to manufacture most parts you need; however, there are distinct differences between these CNC machining products:

Lathe machines have one spindle, two axes (X and Z-axis), and may be flat-bed type making them generally simpler machines.

CNC turning centers can have 3, 4, or 5-axes (including a Y-axis) as well as multiple turrets and sub-spindles. They are usually slant-bed type and have full-machine enclosures that keep the chips and any coolant splashing inside the machine. These types of machines may be able to provide more versatile capabilities and applications, such as turning, drilling, tapping, and milling. Plus, due to the fact that they are completely controlled by a computer, the CNC turning center is able to have great precision when moving on all axes at once.

A turning center can come in both horizontal and vertical structures, with horizontal being the most common for a number of reasons. In these types of applications, a horizontally-oriented spindle allows gravity to make any metal chips fall into the bed below, which means the workpiece can be kept clean during the cutting process.

Best CNC Turning in Toledo, OH | Turning machining China Inc.

As a leading provider of turning, machining, and milling services, we have a deep understanding on what our customers need for sustainable success. We can choose the right machining service to meet your production targets within your budget and on time.

To discuss your production goals or request a quote for CNC turning in Toledo, OH, and CNC machining services, contact Turning machining China Inc. or call +86-755-29621901.